Product Description

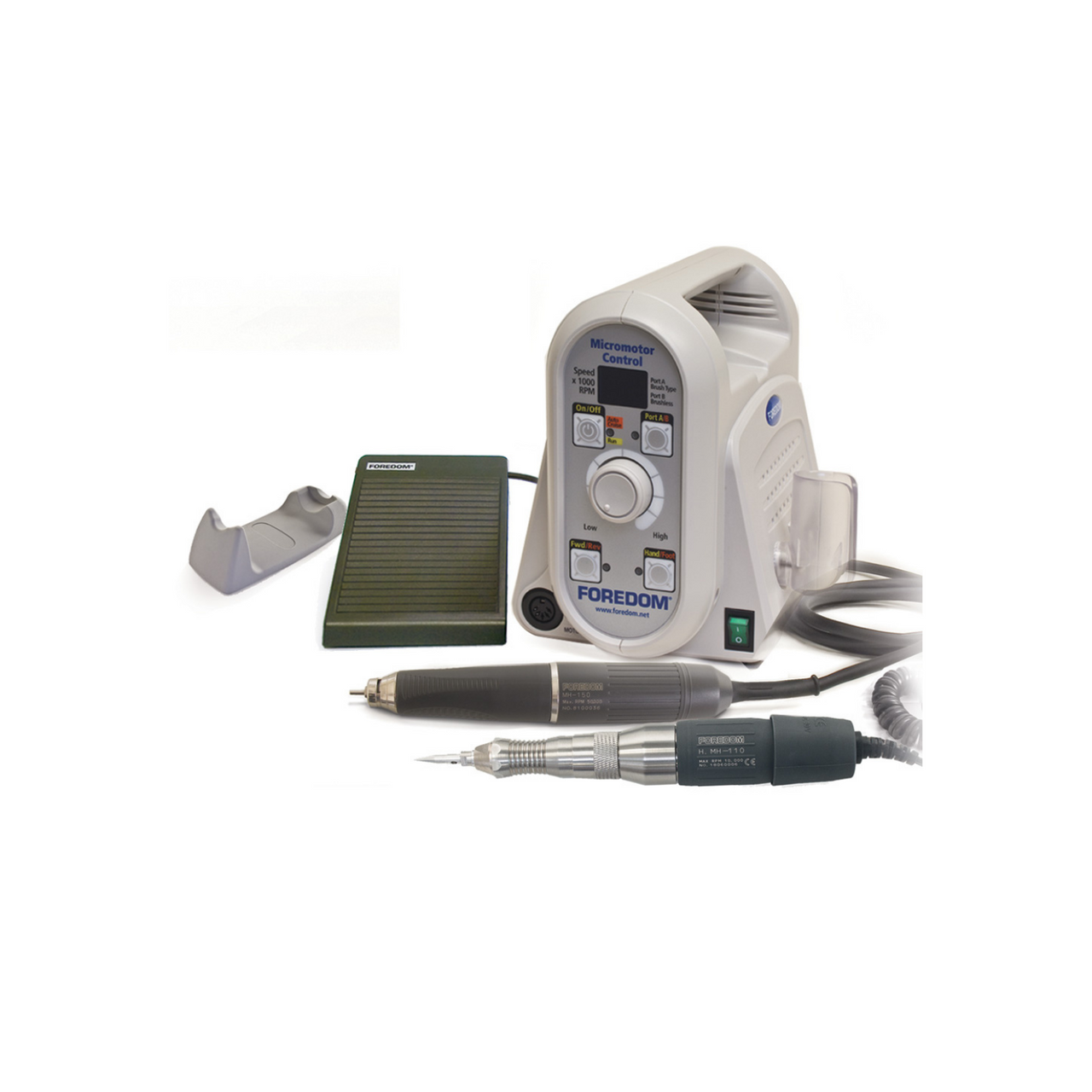

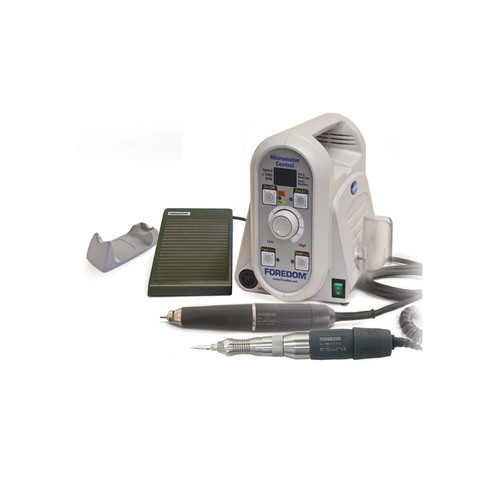

This is one of Foredom's top of the range micromotor kits. This Dual Handpiece kit comes with two handpieces; a fixed size collet version as well as a hammer handpiece.

The high torque and top speed of 50,000 RPM gives you a fast and smooth cut.

No matter what speed you run it at, this unit is virtually noise and vibration free. Set the speed you want and use the footpedal for turning the motor on and off - ideal for when you are using burrs that need a slower speed, like the Typhoon burrs for instance - control the speed and your tools last longer!

The simple cord connection between the handpiece motor and control box is a great advantage. It is very comfortable in the hand, and gives much less strain when being used for longer periods. Compared to a normal flexshaft you get a lot less 'drag' and don't have the same general restriction in manoeuvrability; micromotors offer much greater freedom of movement.

The totally sealed handpiece units keep dust and dirt out so they last longer.

Two handpieces are included in this kit;

Brushless rotary handpiece

This is a fixed size collet handpiece. It connects to port in the back of the control box. It runs virtually vibration free with high torque throughout the entire speed range of 1,000-50,000 rpm. See additional specs below.

- Choose which size collet you want pre-mounted in this handpiece:

-

2.35mm (3/32")

-

3.17mm (1/8")

-

Brushtype Hammer handpiece

This is a reciprocal handpiece which operates at 1,000 – 2,500 strokes per minute. Connects to port in front of the control box. See additional specs below.

Features

- Powerful even at minimum speeds

- Sealed housing eliminates dust, noise, and vibration

- Control box with digital display

- Variable speed foot pedal

- Two handpieces included, one of which a hammer handpiece

- Two handpiece cradles (one freestanding, and one on the side of control box)

- Two year limited warranty

- Maximum torque or watts output 10oz. in or 70mNm or 230W.

This brushless micromotor is ideal for various applications at high, medium and low speed.

- High Speed Applications

- Running at high speed, it provides smooth, clean, and sharp detailing in metal and wood. It’s also great for bright-cutting, grinding, finishing, texturing, and polishing.

- Medium Speed Applications

- At medium speeds it is ideal for effortless and fast stock removal in wood, diestone, or acrylics.

- Low Speed Applications

- The low end offers extra control and power for stone setting, bezel closing, texturing, and milling.

Control Box Specification (HP4-817-2)

- LED Display

- Two ports for handpieces:

- Brushless handpiece (included) connects to port on back of control box (Port B)

- Brush-type handpiece connects to port in front (Port A)

- Control the speed and stop and start the motor using either hand or foot mode;

- Hand - Speed control dial on front of control box, or

- Foot - Foot pedal (included) - will only go up to the maxmimum speed you set at the speed control dial.

- Settings available:

- Auto cruise - allows a preset speed to be held even when the foot pedal is released - work for a long time with no legcramp! :)

- Forward or Reverse rotation

- Dial or Foot speed control

- Digital display for precise speed and torque settings

- Magnetic bur holder on side of control box for your most often used burrs and bits

- Built in overload protection

- 5.4″ wide, 9.1″ deep, 7″ high

- 50/60 Hz, 100VA

Included Brushless Handpiece/Motor - Rotary (H.MH-150)

- Ergonomic and brushless with long-lasting ceramic ball bearings

- Burr changes are quick and easy; just a simple twist of the front section of the handpiece will release the burr

- Depending on which model you choose, it comes pre-installed with either;

- 2.35mm (3/32″) collet, or

- 3.17mm (1/8") collet

- There is also an optional 3mm collet available to add to the kit

- 6.3″ long, 1.06″ motor diameter

- 19mm (0.75)″ grip diameter

- 238gm (8.4 oz)

Included Hammer Handpiece/Motor - Reciprocating (H.MH-110)

- Ideal for stone setting applications, moving metal, closing bezels, and engraving techniques. This handpiece can also be used with the K.1090 micromotor kit.

- Slender contoured grip and impact adjustment ring for precise hammering work.

- Operates from 0-2,500 strokes per minute.

- The force of the impact can be adjusted by simply turning an adjustment ring

- The speed of the hammer action can be varied from 0-2,500 strokes per minute with the dial on the control unit.

- Used with the supplied Graver Holder, the handpiece becomes a precision power engraver - no need for an air compressor or a flexible shaft drive.

- Permanently lubricated ball bearings - no need to lubricate - ever.

- 6-1/4″ overall length, 9/16″ grip diameter, 1″ motor diameter

- 369gm (13oz)

- 0.75 amps (230V)

- NEVER use this in reverse direction as that will damage the handpiece

The Hammer handpiece comes with the following accessories;

- 3 x Anvil Points (tips) with threaded shanks. You get three so the tips can be shaped and modified for different work and operations (HP10177)

- Graver Holder with Allen Key (HPH8-214). This screws into the front end of the handpiece (instead of an Anvil point) and converts it into a power engraving tool. Comes with 5/64″ allen key (graver not included).

- Wrench

- Handpiece Cradle (HP4-933)

- Spare Motor Brushes (HP4-163) - check for wear every 200 hours of use.

- 2 Pins used to tighten Anvil Points

Optional 6 piece Anvil Point Kit is available here.

Included foot speed control (HP7-7060)

- Variable speed foot control, varies speed from 1,000 – 50,000 RPM

- You can set a max speed using the Dial Speed Control which will mean you can't accidentally "rev" to fast with the pedal

- Set AutoCruise - allows a preset speed to be held even when the foot pedal is released - work for a long time with no foot pain! :)

- Plugs in to port on back of control box