Product Description

A favourite of (and must-have tool for) enamelers around the world - this seven piece stackable screen set will fill all your needs for screening and sizing your enamels.

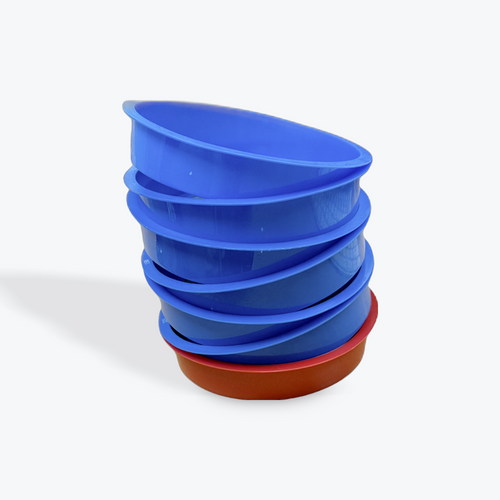

Reduce air bubbles and achieve the best possible clarity when firing your enamels with the help of stackable sifting pans. This set includes 6 x 60-325 mesh screens and one solid pan. Use each screen individually, or stack them to separate the enamel particle sizes. A solid pan on the bottom will catch the fine enamel particles that sift through.

TIP: Get a second solid pan to put on top of the stack when screening to keep floating enamel dust under control. Order one here.

You might have seen enamelist Pam East use these in one of her classes (for instance at the You can make it event in the UK).

The inner diameter of the pan is 125mm (5 1/2").

INSTRUCTIONS FOR USE:

Super fine enamel particles, called 'fines', can cause transparent enamels to appear cloudy. Removing the fines will improve the clarity of your transparent enamels. It is not necessary to screen opaque enamels.

To use the screen, start by nesting it firmly in a solid pan. Place enamel in the screen and add a clean quarter size coin. The coin helps push the enamel through the screen. Nest a second pan firmly on top of the screen to limit the enamel dust introduced into the air. Gently shake the stack back and forth for 15 to 30 seconds. Use the enamel that remains on top of the screen. Discard the fines that end up in the bottom pan.

INCLUDED IN THE SET:

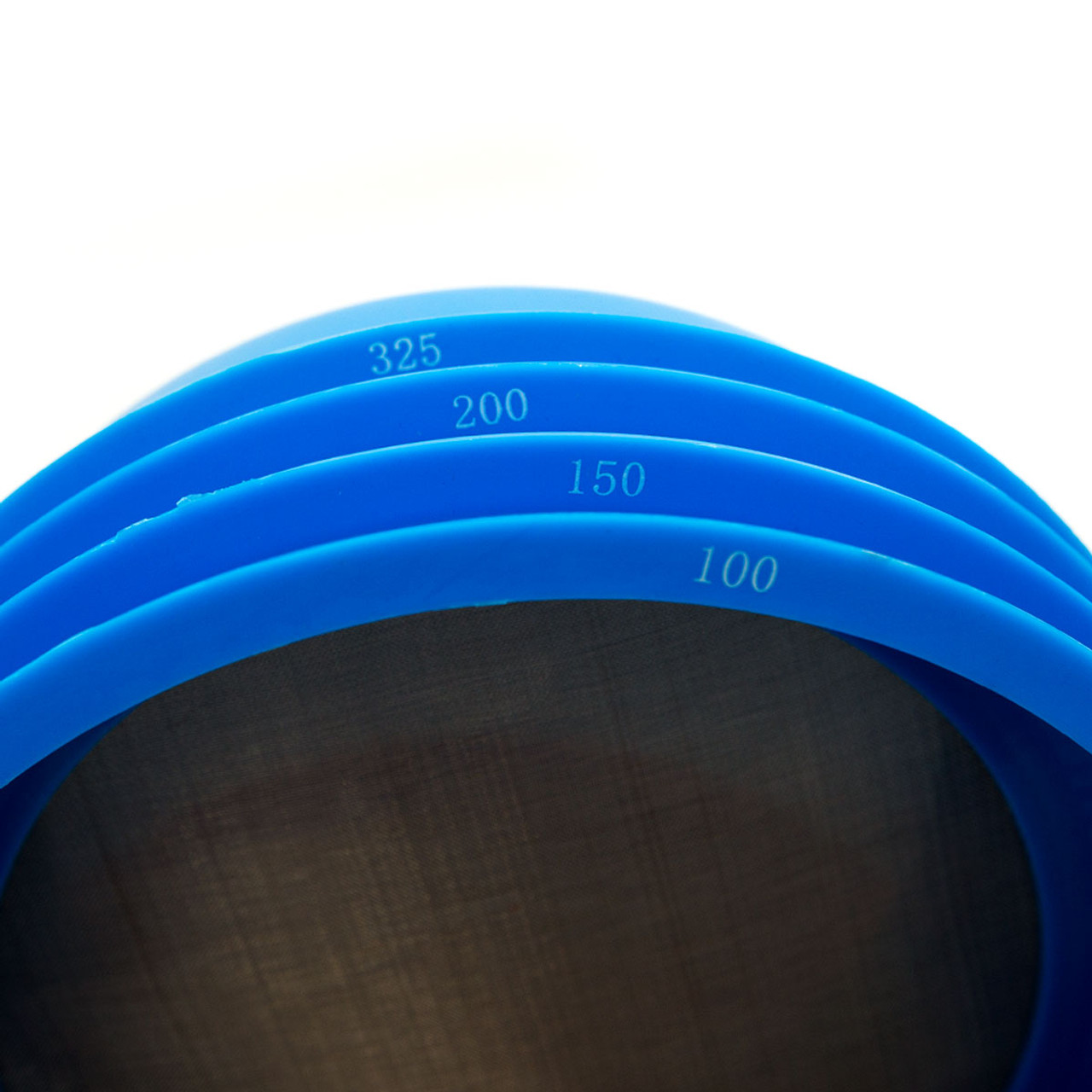

Use these 5-1/2" screens individually or stack them in series to quickly and effectively separate grain sizes during your enameling process. Use the solid pan as a base under the mesh pans. Mesh size is marked on each pan. Set includes seven pans:

- 60-mesh pan

- 80-mesh pan

- 100-mesh pan

- 150-mesh pan

- 200-mesh pan

- 325-mesh pan

- Solid pan

WHAT ARE MESH SIZES?

Mesh size is determined by the number of holes per linear inch. The higher the number, the finer the screen.

200 Mesh - Use this screen for general clarifying of transparent enamels. Works well for most enamelling projects. After screening use the enamel that remains on top of the screen.

150 and 325 Mesh - Transparent enamel can be clarified even more by sizing it through these two screens. This technique is used when enamelling over a detailed texture. Stack the 150 mesh screen on top of the 325 mesh screen with a quarter size coin in each pan. Place solid pans top and bottom. After screening enamel, use the enamel that remains on top of the 325 mesh screen. Enamel on top of the 150 mesh screen may be reserved for future use. Discard the fines in the bottom pan.

100 Mesh. Screening 80 mesh through a 100 mesh screen will produce slightly larger grain size. This is useful when screening clear enamel to be used as a top coat to fill up areas that have already reached the desired colour density. It's also useful for applying a top coat over decorative foils. Enamel in the bottom pan should be reserved for future use.

Safety Note: We recommend you use a dust mask rated N95, P95 or higher when sifting or screening enamels. Some enamel dust will become airborne, and you only have one set of lungs - we think proper safety precautions should be taken. You can purchase one of these masks from us here.

Product Videos

Videos Hide Videos Show Videos

Custom Field

Product Reviews

1 Review

-

Sieves

These are a lot bigger than I thought but I’m really happy with them as can cover a wide surface and lovely quality.