Product Description

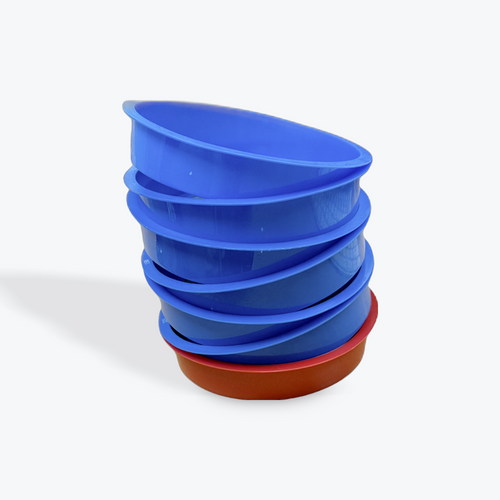

Use enamel mesh screens individually, or stack multiple screens to separate the enamel particle sizes. A solid pan on the bottom will catch the fine enamel particles that sift through. Use a second solid pan on top when screening to keep floating enamel dust under control.

INSTRUCTIONS FOR USE:

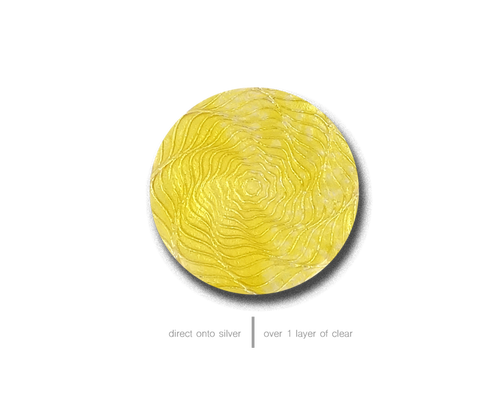

Super fine enamel particles, called 'fines', can cause transparent enamels to appear cloudy. Removing the fines will improve the clarity of your transparent enamels. It is not necessary to screen opaque enamels.

To use the screen, start by nesting it firmly in a solid pan. Place enamel in the screen and add a clean quarter size coin. The coin helps push the enamel through the screen. Nest a second pan firmly on top of the screen to limit the enamel dust introduced into the air. Gently shake the stack back and forth for 15 to 30 seconds. Use the enamel that remains on top of the screen. Discard the fines that end up in the bottom pan.

Safety Note: Always use a dust mask rated N95, P95 or higher when sifting or screening enamels. Even with the caps, enamel dust will become airborne when the stack is opened, so proper safety precautions should be taken. You can purchase one of these masks from us here.

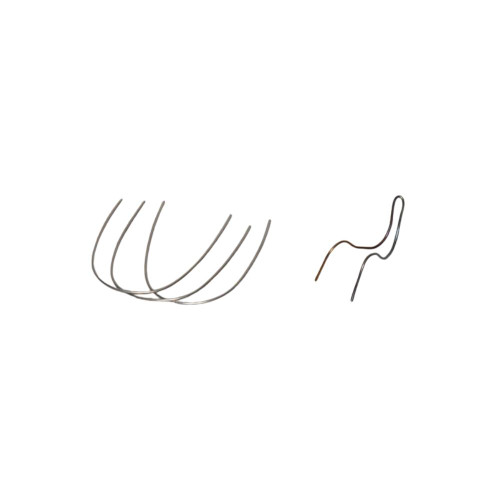

Mesh size is determined by the number of holes per linear inch. The higher the number, the finer the screen.

325 Mesh can be used with the 150 Mesh - Transparent enamel can be clarified even more by sizing it through these two screens. This technique is used when enamelling over a detailed texture. Stack the 150 mesh screen on top of the 325 mesh screen with a quarter size coin in each pan. Place solid pans top and bottom. After screening enamel, use the enamel that remains on top of the 325 mesh screen. Enamel on top of the 150 mesh screen may be reserved for future use. Discard the fines in the bottom pan.

One Sifting Screen included.

See our Enamelling Sifting Screen Set here.

The inner diameter of the pan is 125mm.